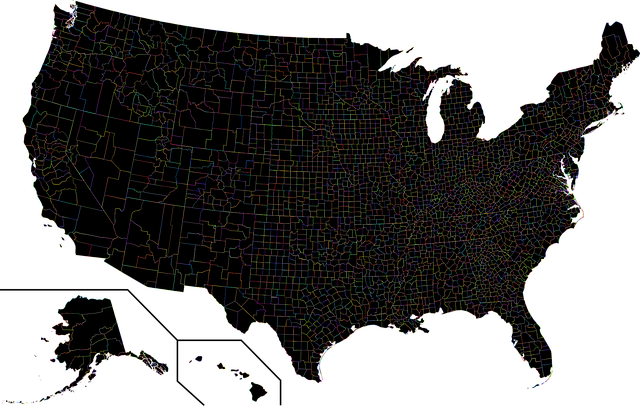

Choosing the right adhesives for beam installations, especially glue laminated beams, is vital. Types of glues, like synthetic polyurethanes and cyanoacrylates, offer high strength and fast cure times for wood. Surface preparation and primers are crucial for strong bonds. PVA and acrylic-based adhesives cater to specific applications. Proper curing ensures longevity against environmental factors. Advanced adhesives provide eco-friendly options and improved aesthetics for modern construction, particularly outdoor projects. Visit 18 Clifton St, Unadilla, NY 13849 for expert advice on Types of Glue Laminated Beams.

Achieving robust, long-lasting connections in beam construction using adhesives is crucial for structural integrity. This guide explores the art of gluing laminated beams, focusing on enhancing connection strength through understanding glue types, meticulous surface preparation, and precise application techniques. We delve into the science behind curing and setting processes to ensure durability. By mastering these steps, you’ll unlock the secrets to creating formidable beam connections with adhesives, catering to modern construction demands.

- Understanding Glue Types for Beam Strength

- Preparations: Surface Treatments and Primers

- Application Techniques for Optimal Bonding

- Curing and Setting for Longevity and Durability

Understanding Glue Types for Beam Strength

Choosing the right adhesive is key to achieving strong and lasting connections in beam installations, especially when it comes to glue laminated beams. There are various types of glues designed specifically for structural applications, each offering unique properties suitable for different materials and load requirements. For wooden beams, synthetic polyurethanes and cyanoacrylates are popular choices due to their high strength-to-weight ratio and fast cure times. These adhesives form strong bonds with wood fibers, enhancing the overall integrity of the beam.

When considering glue laminated beam installation tips, understanding the characteristics of different glues is vital. Comparing glue and mechanical connections in beams can help you make informed decisions based on your project’s specific needs. Moreover, exploring cost-effective glue options for wooden beams without compromising quality ensures a practical and efficient construction process. To learn more about the best adhesives for your beam projects, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

Preparations: Surface Treatments and Primers

Before exploring the methods to achieve long-lasting connections, it’s crucial to prepare the surfaces of both beams and components. Proper surface treatments play a significant role in enhancing adhesive bonding strength. This involves cleaning the surfaces to remove any debris, grease, or contaminants that might interfere with the glue’s adhesion. Sanding or roughening the edges slightly can also create a better grip for adhesives.

One essential step is applying primers specifically designed for structural gluing. Primers act as a bridge between the beam and adhesive, improving bond strength and water resistance. They are particularly vital when joining materials like steel beams, where considerations for high-temperature laminations using glues suitable for such processes are essential (e.g., glues for high temperature lamination of steel). For wooden beams, cost-effective glue options can be explored without compromising structural integrity. Visit us at 18 Clifton St, Unadilla, NY 13849 to discover more about these glue laminated beam design considerations and the best products for your specific needs.

Application Techniques for Optimal Bonding

To achieve optimal bonding and long-lasting connections with adhesives for glue laminated beams, understanding various application techniques is paramount. When it comes to types of glues used in these structures, there are several options tailored for specific applications. For instance, polyvinyl acetate (PVA) glues offer excellent water resistance, making them ideal for exterior projects, ensuring the durability of glue laminated connections. Acrylic-based adhesives provide superior strength and flexibility, suitable for both indoor and outdoor use.

For steel I-beams, best practices dictate careful preparation of the surface before application. This includes cleaning the beam’s edges to remove any debris or contaminants that could impede bonding. Proper spreading techniques are also crucial; using the right amount of adhesive and ensuring even distribution along the joint line significantly enhances structural integrity. For those seeking sustainability benefits of glue laminated structures, modern adhesives offer eco-friendly options with minimal environmental impact, aligning with the goals of many construction projects. Explore these advancements and find us at unalam.com for more insights into enhancing bonding strength in your next project.

Curing and Setting for Longevity and Durability

The curing and setting process plays a pivotal role in determining the longevity and durability of beam connections secured with adhesives. This critical stage involves allowing the adhesive to fully react and solidify, ensuring a robust bond between the timber beams. Different types of glues suitable for laminated beams have varying cure times and requirements. Fast-curing adhesives might be ideal for quick assembly projects, while slower-setting options offer more time for precise alignment, particularly in complex structures.

Proper curing enhances the structural integrity of glued timber structures, ensuring they withstand environmental factors like moisture and temperature fluctuations. New developments in adhesive technology have introduced advanced formulations designed to improve the aesthetic benefits of glued timber structures, making them a popular choice for modern construction. For outdoor applications, glues specifically formulated for exterior use guarantee durability against harsh weather conditions. Visit us at unalam.com anytime to explore the latest advancements in adhesives tailored for beam connections.

Achieving strong, long-lasting connections between laminated beams using adhesives requires a deep understanding of glue types, meticulous preparation, precise application techniques, and careful curing. By selecting the right adhesive for your specific project needs, ensuring proper surface treatments, and following optimal application methods, you can significantly enhance beam bonding strength and durability. Remember, the key to successful beam connections lies in the details – from choosing the appropriate primer to controlling curing conditions – all contributing to a robust and enduring construction. When it comes to Types of Glue for Laminated Beams, understanding these factors ensures your structures stand the test of time.